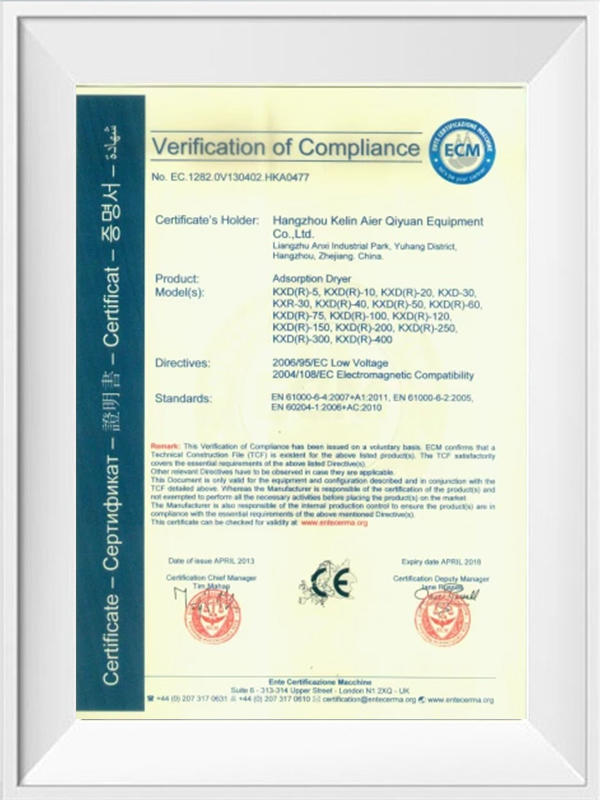

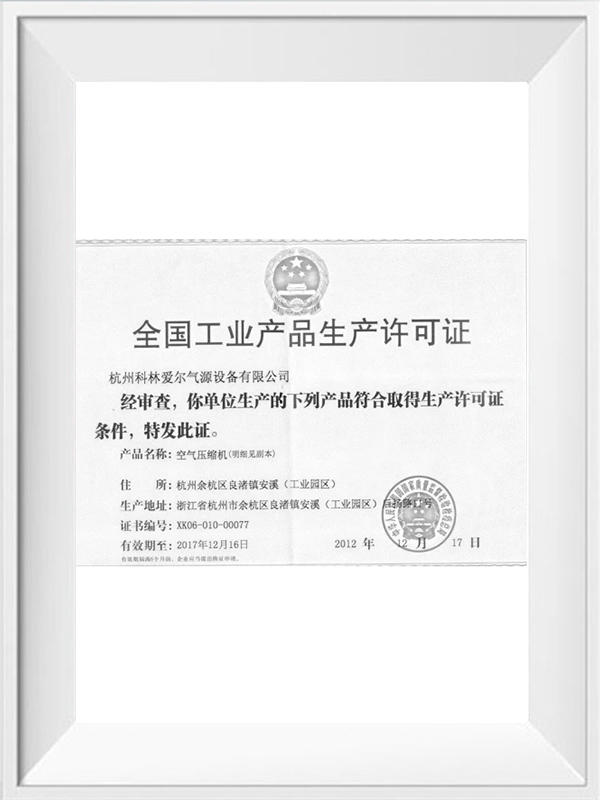

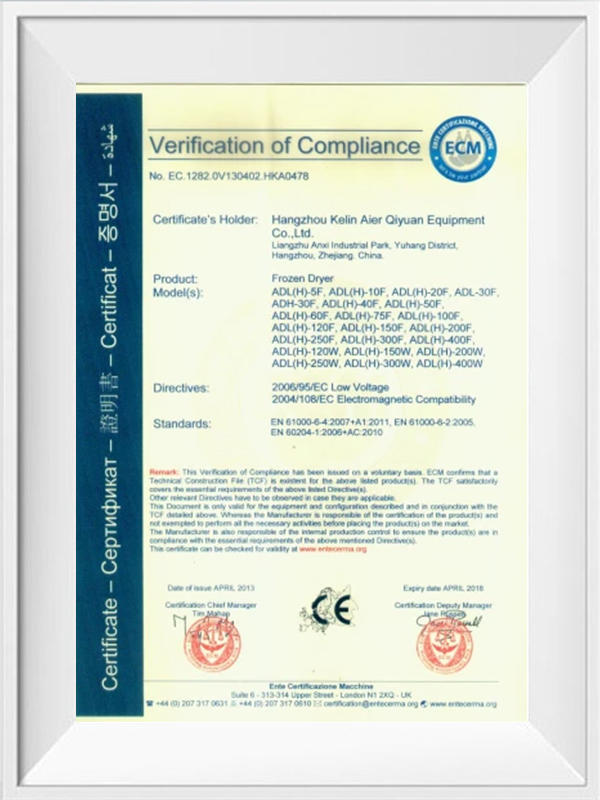

KL company is China Desiccant air dryers manufacturers and wholesale Desiccant air dryers factory. The company was established in 1997, dedicated in the promotion and design of compressed air purifying equipments, The leading product is refrigerated air dryer, desiccant air dryer, compressed air filter, water chiller , nitrogen / oxygen generator. KL air dryer company have the CE certificate and could provide the ASME code air dryer for customer. KL covers an area of thirteen thousand square meters, having over 125 workers (16 professional management staffs and 15 professional senior technical engineers).Currently, KL company produced more than 8,000 units drying equipment and more than 30000 units filters & oil separator, (of which 30% are exported to the international market). KL factory under 6S manage system and quality standard by ISO9001.

Bank Name: AGRICULTURAL BANK OF CHINA,HANGZHOU BR,LIANGZHU SUB-BR

Bank add: No.1639,Moganshan Road,Liangzhu town, Yuhang District,Hangzhou City,China.

Account No.:1905 091404 0000060

Swift: ABOCCNBJ110

English

English Español

Español

-1.png?imageView2/2/w/500/h/500/format/jpg/q/100)